Recognition of Suitability

News

News

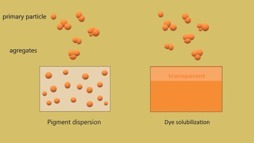

Coloration can be achieved using organic and inorganic pigments, solvent, disperse and other polymer soluble dyes. Effect pigments such as: aluminium and bronze powders, pearlescent and phosphorescent pigments can be added to enhance the optical properties of plastics. Pearlescent pigments can be used in certain instances to impart laser marking properties.

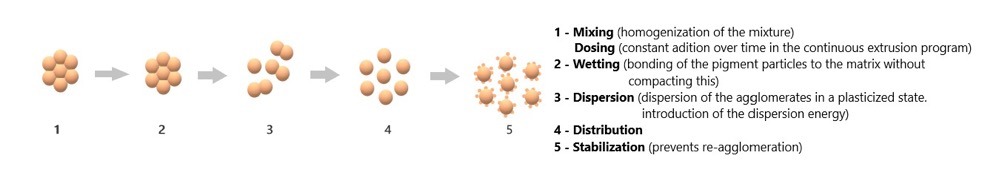

Pigment preparations made up of finely dispersed pigment particles in a polymeric or polymer compatible material are often used in dispersion critical applications. Pigments require a high level of dispersion to breakdown agglomerates which occur in the production process, transportation and storage of these colorants. The physics of dispersion involve the breaking down of the internal forces that hold the primary pigment particles together in an agglomerated form. The aim of dispersion is to produce a homogeneous mixture of carrier and pigment which is compatible with the end polymer to be coloured.

The dispersion degree of the pigments is the key point of the masterbatch production process and it depends on the physical properties of pigment particle (i.e. size, shape, surface properties, crystalline structure, chemical composition of the primary crystals), the pigment concentration in colour masterbatch and, most important, on the process parameters involved during extrusion, because a lot of mechanical work is required, which in the case of inadequate equipment, leads to degradation of pigments and polymers.

The goal when manufacturing masterbatches is the optimum dispersion and distribution of the additives in the polymer matrix. This is carried out after wetting by the mechanical energy introduced by the screws. If this takes place too early in the process, the un-moistened pigments can be compressed back into agglomerates by the force exerted on them (cold agglomeration).

In addition, this new equipment has the possibility of producing colour masterbatches with high levels of pigment, ensuring homogeneity throughout all the batches produced and with the following advantages:

- better base polymer and pigment quality

- less use of dispersing agents that "contaminate" the polymer chains

- better dispersion having the same % pigment with better yields, leading to a customer dosage reduction of 5-10%.

Upon request, our colour masterbatch is adapted to conform exactly to specific customer requirements in several application areas, making us the solution to present you a premium-quality colour masterbatch and offer you a high level of quality for highly demand requests as for food, cosmetics and lifestyle industries.

ISOCOLOR NEW SERIES offers you a wide colour space of high demand colours. These colours are maintained at a consistent stock level at all times and are readily available. The dispersion of our products is rigorously tested to meet dispersion specifications for the most challenging applications, including thin gauge film.

ISOCOLOR NEW SERIES brings breadth and depth of colour performance to your plastics, using pigments, preparations and the most updated equipments that deliver consistent, reliable and outstanding quality.